Best Practices for Building Supply Chain Resilience

The global economy has been increasingly unstable in recent years, with supply chain disruptions becoming more frequent and widespread. In order to remain competitive and agile in the market, companies must develop a resilient supply chain network capable of responding quickly to sudden changes. This blog post will discuss best practices for building supply chain resilience, from setting up a resilient network to leveraging technology to measure performance. With the right strategies in place, businesses can be better prepared for unexpected disruptions and protect their bottom line.

The coronavirus pandemic has revealed considerable weaknesses in the global supply chain: With national lockdowns and factory closures in major supplier countries, such as China, companies have had to explore creative alternative sources for raw materials. Despite COVID-19's unprecedented nature, disruption of this scope is not a new phenomenon. From geopolitical events to natural disasters, there are any number of scenarios that can introduce risk and destabilize the global supply chain.

Introduction:

Resilience is a key factor in successful supply chain management. A resilient supply chain can efficiently adapt to sudden changes, reduce its risks, and improve efficiency. In this blog post, we'll discuss best practices for building a resilient supply chain that is capable of meeting the demands of the modern world. We'll examine strategies and techniques businesses can use to ensure their supplies are secured, reduce costs, and increase long-term sustainability.

This entire transformation journey began when Sudha applied for a position at TELCO and noticed that the footnote prohibited female candidates. She wrote to JRD Tata about the gender bias issue and was granted a special interview, eventually becoming a development engineer.

Setting up a resilient supply chain network

Setting up a resilient supply chain network is key to any organization's success. A well-defined and efficient supply chain network ensures that the delivery of materials and services is done on time, at the right cost, and with the highest quality. It involves creating a robust set of processes, systems, and relationships between all stakeholders in order to ensure the successful flow of goods from supplier to customer. To do this, businesses must assess their current supply chain capabilities and map out an expected future state within their industry. It also requires strategic decision-making to determine what technology investments should be made in order to improve the efficiency and reliability of the network. Finally, effective communication and collaboration between suppliers, partners, customers, and other stakeholders can go a long way in establishing a reliable distribution system. When followed properly these steps establish an integral structure that provides organizations with greater resilience needed for continued success.

Utilizing Risk Management Strategies

When building supply chain resilience, businesses should consider utilizing risk management strategies. This could include conducting regular reviews to identify potential risks and developing proactive plans to address them. Companies should also review their current processes for evaluating, addressing, and monitoring risk management strategies. They can then make sure that any changes or adjustments in the way they operate are incorporated into these strategies. Additionally, companies should evaluate the use of third-party suppliers or sub-contractors within their supply chain to further reduce risk. By taking a proactive approach to managing potential risks within their supply chain, businesses can ensure that they are best positioned for success in the long run.

Ensuring Internal Communication and Collaboration

Effective internal communication and collaboration are essential to building resilient supply chains. Organizations can take steps to ensure their internal communication networks are secure, reliable, and always working properly. First, they should invest in a comprehensive teamwork platform that allows team members to quickly share information, understand each other's perspectives, and assign tasks. Additionally, it is important for organizations to create clear guidelines on how best to collaborate with other teams or departments. These guidelines should be updated regularly so stakeholders can stay up-to-date with the latest changes and developments in the organization’s operations. Finally, organizations should ensure that employees have access to the right training materials and resources needed for successful collaboration across different parts of the supply chain. Adopting these practices will bolster internal communication systems within an organization and strengthen its overall supply chain resilience.

Leveraging Technology for Automation and Efficiency.

In order to build supply chain resilience, leveraging technology for automation and efficiency is essential. Automation allows businesses to reduce labor costs while increasing speed and accuracy in many aspects of the supply chain process. Using digital tools like analytics, machine learning, and artificial intelligence can help businesses identify possible disruptions faster than ever before and provide automated solutions that help them adjust quickly and minimize any potential disruption or downtime. Additionally, efficient technologies can enable companies to quickly track their inventory levels and optimize their resources accordingly. By incorporating these technologies into their business strategies, companies can ensure they are better prepared for future disruptions and have a stronger supply chain overall.

Engaging Supplier and other partners in Resiliency Planning

Supply chain resiliency involves more than just a company's internal operations. Engaging external suppliers and partners is an essential part of developing comprehensive plans for dealing with unexpected disruptions. Joint resiliency planning is a collaborative process whereby companies can develop proactive strategies to mitigate risks across the entire supply chain. Companies should involve their key suppliers and partners in risk assessment, mapping out potential weaknesses and vulnerabilities, understanding the impact of any disruption, and determining agreed-upon best practices that both sides can use to minimize any adverse effects. By engaging with suppliers and partners on joint resiliency planning initiatives, companies can ensure they are taking advantage of all available resources to support their overall supply chain strategy.

Measuring and Monitoring Supply Chain Resiliency Performance.

Measuring and monitoring supply chain resiliency performance is key to ensuring your organization's supply chain can successfully confront any disruptions. By tracking key performance indicators (KPIs) such as on-time delivery rate, inventory levels, and customer satisfaction scores, organizations can quickly identify potential issues within their supply chain that could lead to disruption. Additionally, investing in technology tools that monitor different elements of the supply chain including suppliers and third-party logistics providers can help you anticipate challenges before they occur. When properly monitored and acted upon, KPIs provide real-time data for measuring the success of a company’s supply chain resilience initiatives.

Conclusion:

In conclusion, building supply chain resilience requires an understanding of all elements and potential risks associated with your company's operations. As the business environment evolves, it is important to take proactive steps to increase your supply chain's flexibility in order to ensure effective response and adaptation. Utilizing the best practices identified in this article can help you improve visibility, build agility, and strengthen communication across the entire organization for greater success. With clear goals, effective strategies, and a commitment to continuously learn from new developments, you will be well-positioned to survive any challenges that may arise.

Share This Blog, Choose Your Platform!

RELATED BLOGS

Blog Summary Firebird Institute's PGDM program ai...

Read More

About Firebird The Firebird Institute of Research...

Read More

Introduction The students of Firebird Institute o...

Read More

In the rapidly evolving world of business, choosin...

Read More

The CAT 2024 results have been officially anno...

Read More

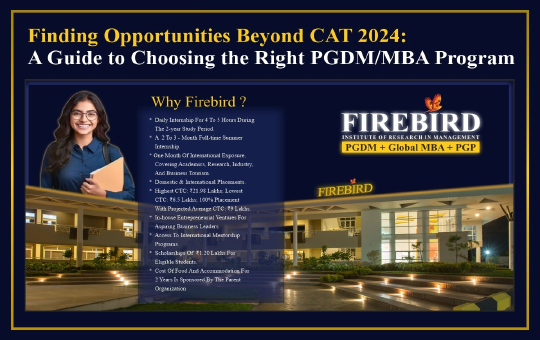

A Guide to Choosing the Right PGDM/GLOBAL MBA Pro...

Read More

Why Pursue a PGDM/GLOBAL MBA Degree in 2025? As ...

Read More

The closing ceremony at Multimedia University (MM...

Read More

As one of the top PGDM/Global MBA colleges in Coi...

Read More

Firebird Institute of Research in Management, rec...

Read More

A Grand Procession: Setting the Tone The Convocat...

Read More

The Firebird Institute of Research in Management, ...

Read More

Overview The Firebird Institute of Research in Ma...

Read More

Firebird Students Head to Multimedia University fo...

Read More

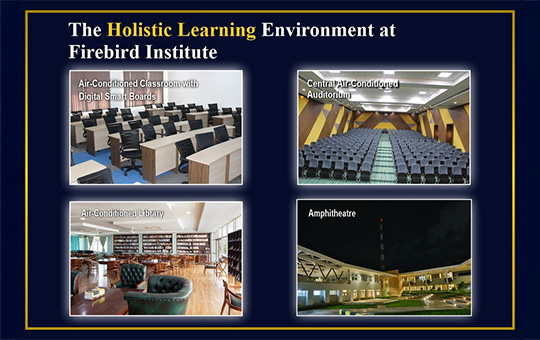

A Campus That Combines Nature with World-Class In...

Read More

The vibrant energy of Firebird Institute of Resear...

Read More

A Celebration of Academic Excellence and Cultural ...

Read More

About Firebird Firebird Institute of Research in ...

Read More

Overview Firebird Institute of Research in Manage...

Read More

Overview The Firebird Institute of Research in Ma...

Read More

Overview The Firebird Institute of Research in Ma...

Read More

Overview The convocation ceremony at Firebird Ins...

Read More

Firebird Institute of Research in Management: CEO ...

Read More

Overview In today's dynamic world, the boundaries...

Read More

Exploring the Comprehensive Support Services for F...

Read More

Overview: At the Firebird Institute of Research...

Read More

Overview: In today’s dynamic business environ...

Read More

Comments